[Global news]Bio Friends Leads DME, rDME & DME-H2 Projects in Asia

Biofirends Admin

view : 469

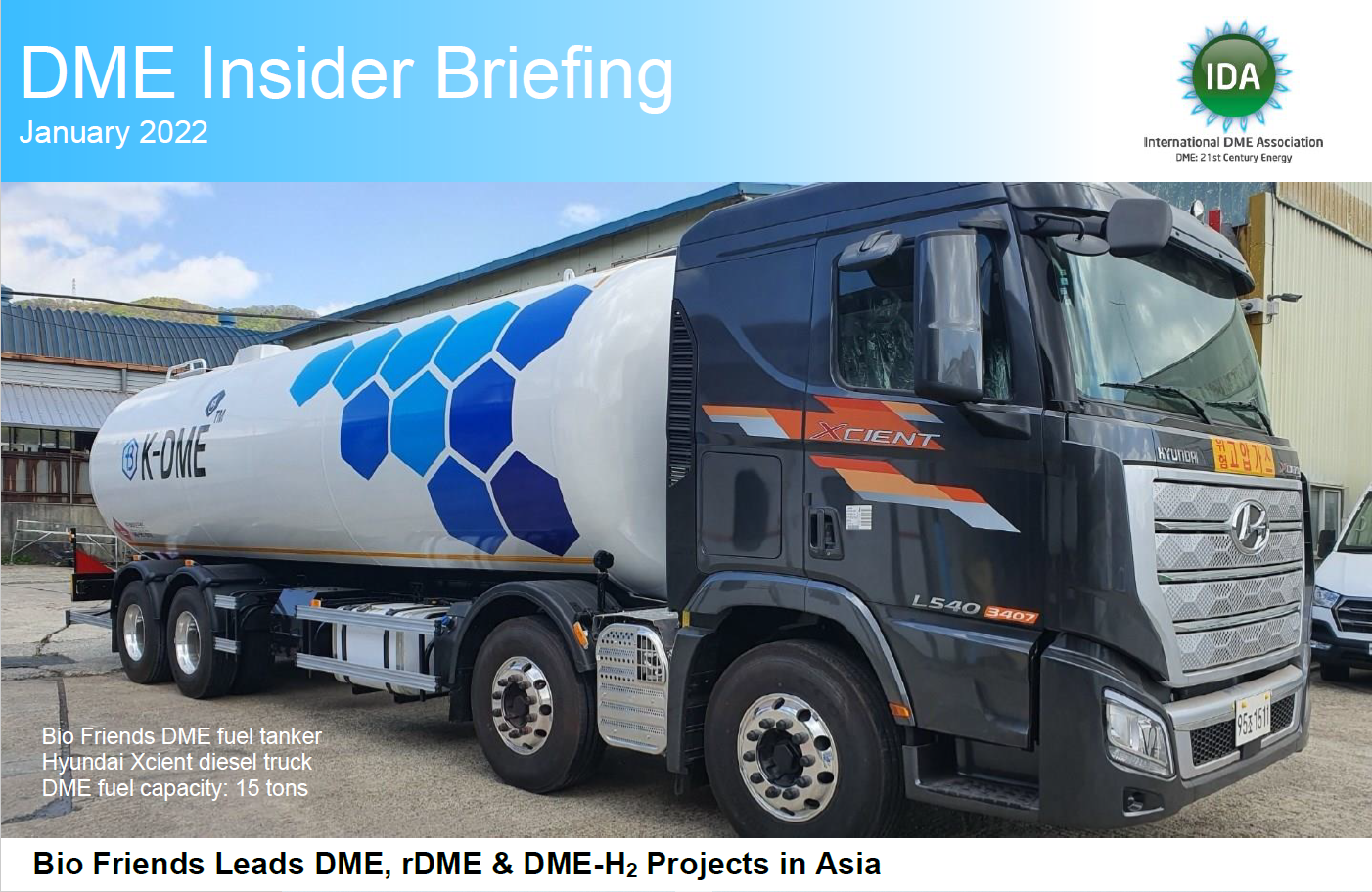

▲Bio Friends DME fuel tanker Hyundai Xcient diesel truck DME fuel capacity: 15 tons

Bio Friends Leads DME, rDME & DME-H2 Projects in Asia

10 January 2022 |

Plans announced by South Korean DME manufacturer Bio Friends include leadership of a ₩39 billion (US million) national project for the production of low-carbon fuels using CO2 captured from cement industry emissions, and a ₩4 billion (US .3 million) project utilizing the company’s DME-H2 reformer for heating and power generation, both the first such projects in the region.

Bio Friends began producing DME in late 2020 at its 5,000 ton per year (TPY) facility at the Boeun Industrial Complex in North Chungcheong Province (photo right), and currently supplies DME to customers in South Korea for fuel, aerosol propellant, blowing agent and refrigerant applications. To date the plant has used fossil-derived methanol as a feedstock, but this year will begin producing rDME using renewable methanol for blending (33.3% wt) with (fossil) DME. A second DME production plant, with a capacity of 10,000 TPY, is currently under construction near the existing facility and scheduled to commence operation in early 2023.

Production, Logistics and Applications Demonstrated

In addition to its core DME production business, Bio Friends has technology research and project development activities involving DME, rDME, LPG-DME blends and hydrogen, alone and in cooperation with partners including Engine Tech Win, Doowon Precision Industry, Korea Institute of Energy Research (KIER) and Korea Automotive Technology Institute (KATECH), across numerous application areas:

- Sustainable mobility: DME engine, and vehicle retrofitting for DME fuel use

- Logistics: DME transport, storage, distribution and dispensing

- Power generation: various capacity DME power generators

- LPG-DME blends: industrial heating and manufacturing processes

- Hydrogen: DME-to-hydrogen reforming process and fuel cell

DME-fueled engines developed by Bio Friends and Doowon Precision were demonstrated in three vehicles for a combined total of 40,000 km. The engines, based on a modified 3.9 liter Hyundai Kia diesel engine, can be used in vehicles and for power generation

CO2 Capture, Renewable Methanol and rDME from Cement Industry Emissions

South Korea has announced plans to achieve carbon neutrality by 2050, including investment in technologies to reduce emissions in emission-intensive industry sectors such as steel, petrochemicals and cement. Bio Friends was selected to lead a project supported by the Ministry of Trade, Industry and Energy for the “Development of Low-Carbon Fuel Synthesis Using Captured CO2 from the Cement Industry (CCU) Sector”. The project, with a budget of ₩39 billion (US million), involves demonstration of a 50 tpd CO2 capture and 30 tpd methanol synthesis facility at the Sungshin Cement Company’s plant in Danyang. Sungshin has stated a goal of scaling up CO2 capture to 400 tpd by 2027 and 2,000 tpd by 2030. Bio Friends plans to use this methanol to produce rDME at their facility. With almost half of all cement production plants in South Korea located in North Chungcheong Province, there is significant opportunity for other cement producers to leverage the technology developments being made in the region.

DME-to-Hydrogen Demonstration

Another national project announced last year and commencing this month involves demonstration of a DME-fueled hydrogen fuel cell in off-grid commercial agriculture, using the exhaust gas as a heat source in winter and with a heat pump for cooling in summer. The three-year project, “DME Fuel Cell Exhaust Heat Recirculation for Greenhouses and CO2 Utilization”, is supported by the Ministry of Agriculture, Food and Rural Affairs and has a budget of ₩4 billion (US .3 million). Bio Friends has performed numerous technology evaluations and demonstrations in the agriculture sector, including DME-fueled greenhouse power generation, boilers, heaters and CO2 generators.

The company’s Chief Executive Officer, Dr. Wonjun Cho, previously led DME R&D at Korea Gas Corporation (KOGAS), and begins serving as chairman of the Korea DME Association (KDA) this year. He commented that “success in producing rDME from CO2 captured from the cement industry could not only contribute to the reduction of greenhouse gas emissions, but could also create a monumental ripple effect on emission-intensive sectors closely related to the cement industry, such as steel and iron”.

More information: en.bfi.co.kr

(sauce: International DME Association-DME Insider Briefing)

02 - 6739 - 1100~3

02 - 6739 - 1100~3 bftech@bfi.co.kr

bftech@bfi.co.kr